Quick Summary:

● Pallet damage can lead to financial losses, operational inefficiencies, safety risks, and reputational damage.

● Common causes include poor handling, overloading, improper stacking, environmental conditions, incompatible pallets, and low-quality materials.

● The consequences of damaged pallets range from product loss and increased logistics costs to delays, safety hazards, and loss of customer trust.

● Pallet safety tips to prevent and minimise pallet damage include staff training, investing in quality pallets, using proper handling equipment, optimising warehouse layout, regular inspections, structured policies, and adopting modern technology.

● Partnering with the right warehousing providers, like Cargoz in the UAE, helps businesses find a reliable warehouse that reduces pallet handling risks, improves efficiency, and protects product integrity.

Pallet damage may seem like a minor issue in warehouse operations, but it can lead to significant financial losses and damage to a brand's reputation. According to the Food Marketing Institute (FMI) report, the grocery industry loses about $20 billion in damaged goods yearly, and one of the primary reasons is broken or damaged pallets.

However, the impact of pallet damage is not only limited to the food industry but can also cause internal damage to fragile goods. For example, a poor pallet can cause damage to glassware or electronics during transportation, even if they appear intact on the outside.

That's why minimising damage to pallets is essential to prevent loss and optimise productivity in warehousing operations. In this guide, we will explore the top reasons and consequences of pallet damage and provide the best pallet safety tips to prevent or minimise damage.

Table of Contents |

● Understanding Pallet Damage: Causes and Consequences ● How to Minimise Pallet Damage: Key Safety Tips and Practices ● Final Thought ● Frequently Asked Questions |

Understanding Pallet Damage: Causes and Consequences

Pallet damage can disrupt even the most well-organised supply chains, resulting in operational inefficiencies and losses. That's why understanding the primary reasons for pallet damage and their consequences is crucial to safeguard product integrity, prevent workplace accidents, and maintain a smooth operational flow.

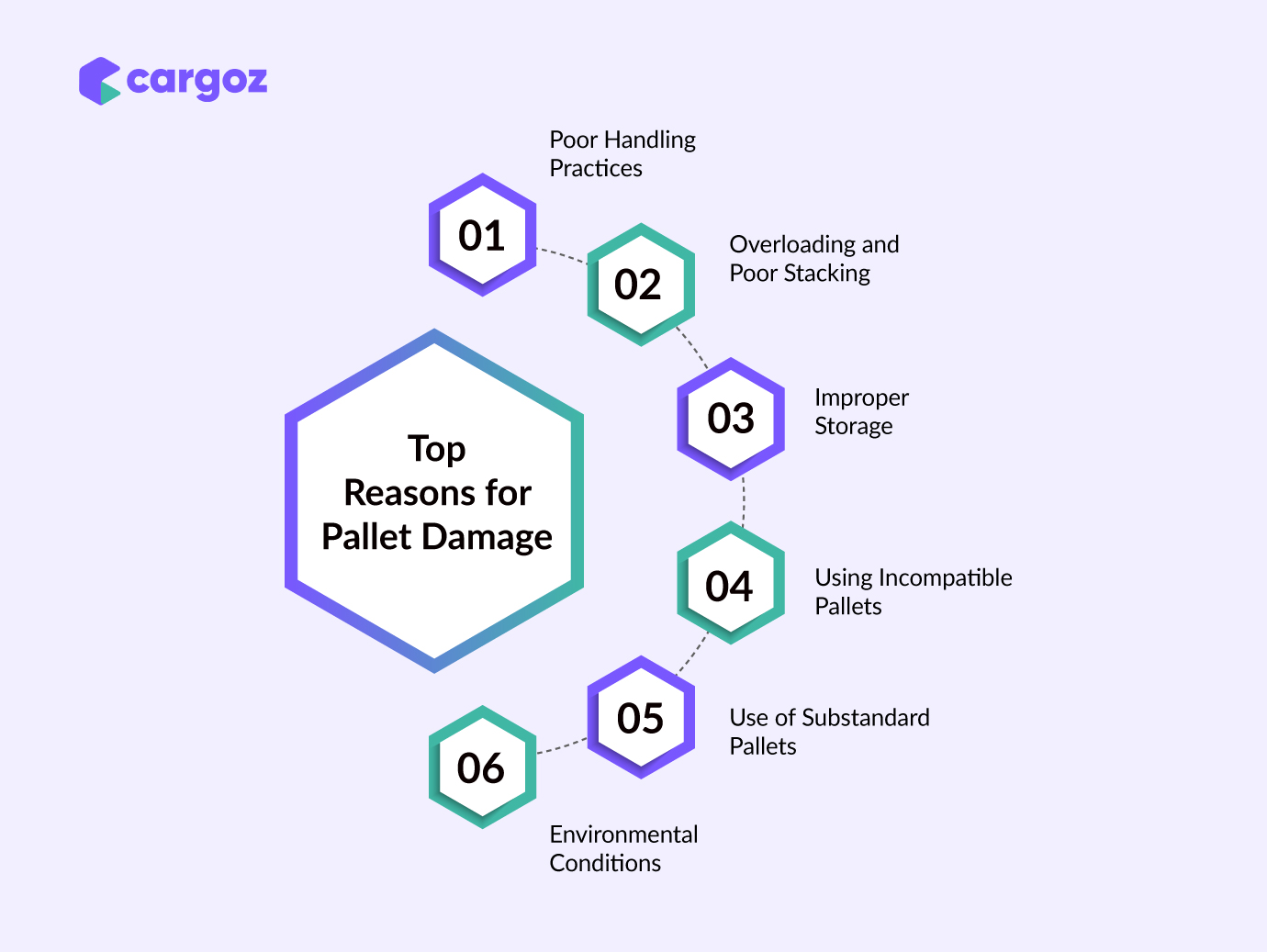

6 Common Causes of Pallet Damage

Damage often results from a combination of handling errors, environmental factors, and improper storage. Identifying these causes and following pallet safety tips helps you create effective prevention strategies.

Poor Handling Practices

Using forklifts or pallet jacks incorrectly, such as dragging pallets instead of lifting them, and stacking products beyond the weight limits, can damage pallets or cause breakage.

Overloading and Poor Stacking

Businesses use pallet racking systems instead of floor stacking to distribute weight evenly and prevent goods from damage. However, improper stacking of pallets can still cause damage to goods.

If you learn which storage method best fits your operations, explore our guide on Pallet Racking vs. Floor Stacking.

Improper Storage

Leaning pallets against walls, stacking them irregularly, or storing them on uneven flooring increases the risk of warping and splintering.

Using Incompatible Pallets

Using pallets not designed for specific weight, shape, or type of goods can cause damage due to wear and tear.

For example, lightweight or single-use pallets can't withstand the stress of repeated handling or heavy loads, which will result in cracked boards or deformed structures.

Use of Substandard Pallets

Using poor-quality pallets or reusing pallets with structural flaws, missing boards, or loose fastenings can cause breakage and compromised load stability.

Environmental Conditions

Exposure to extreme heat, excessive moisture, or fluctuating temperatures weakens wooden, plastic, and even metal pallets, reducing their lifespan.

Consequences of Pallet Damage on Businesses

The impact of pallet damage includes product loss, financial loss, safety hazards, operational delays, and reputational damage. Let's look at them in detail.

1. Product Loss and Financial Setbacks

Damaged pallets can cause goods to fall, spill, or shift, causing damage to products during transit. This will result in breakage, returns, and increased insurance claims. Understanding how to reduce product damage in warehouse operations is crucial for saving costs and protecting inventory.

2. Safety Hazards

Broken pallets create sharp edges, loose nails, and unstable or collapsed stacks, which can cause injury to warehouse staff and drivers. It might also lead to regulatory actions and penalties.

3. Operational Delays

Damaged pallets slow down the workflow, disrupt loading schedules, and delay shipments. You must repack and resend the shipment, which significantly reduces warehouse efficiency.

4. Increased Logistics Costs

Repairing or replacing damaged pallets, compensating for lost goods, and implementing corrective measures requires additional resources, which can impact the bottom line.

5. Brand and Customer Trust Issues

Delivering goods on broken pallets can cause product damage, negatively impacting business reliability and reputation. Frequent delivery of damaged goods also affects trust and relationships with customers and partners.

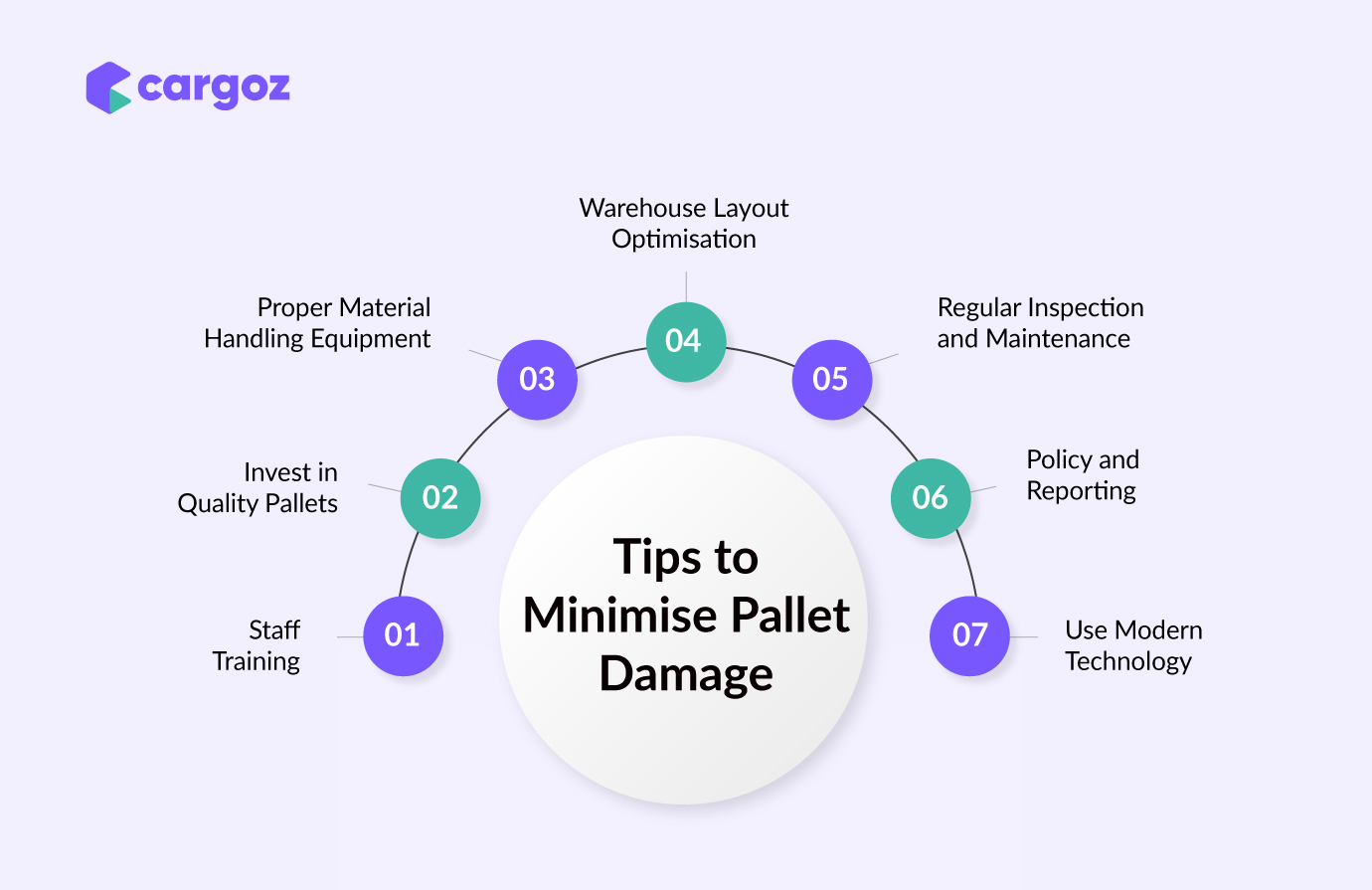

How to Minimise Pallet Damage: Key Safety Tips and Practices

Pallet rack damage can impact businesses financially and erode customers' trust and reliability. Following proper pallet safety tips can significantly reduce damage, enhance workplace safety, and maintain product quality. Here are the best practices to reduce pallet damage.

1. Staff Training

Your employees work with pallets, and their efforts can significantly reduce pallet damage. Proper training ensures safe handling and reduces avoidable mistakes.

● Educate staff on correct loading, stacking, and forklift operation techniques.

● Specify weight limits and ensure your employees follow them correctly.

● Conduct refresher sessions regularly to maintain awareness.

2. Invest in Quality Pallets

Low-quality pallets may be cheaper upfront, but with frequent damage, they will be costlier in the long run.

● Select pallets based on your product requirements, whether they are made of wood, plastic, or composite materials.

●Choose standardized pallets that are compatible with racking and automation systems.

● Don’t buy cheap pallets for short-term savings; instead, focus on durability and reusability for the long term.

Suggested Read: Different Types of Pallets in Warehouses and Their Usage

3. Proper Material Handling Equipment

Using the right equipment suited to your pallet types prevents misalignment, excessive force, and accidental drops that lead to structural damage.

●Deploy forklifts, pallet jacks, and automated handling systems designed for the specific pallet type.

●Ensure forklift tines are properly adjusted to avoid cracking or splintering.

4. Warehouse Layout Optimisation

A well-organised warehouse layout with wider aisles, smooth surfaces, and clear pathways ensures safer movement and minimises the chances of accidents.

●Design clear pathways for equipment movement to avoid collisions.

●Install racking systems suited to the pallet size and load capacity.

● Maintain smooth, even flooring to prevent tipping or warping.

5. Regular Inspection and Maintenance

Checking pallet condition regularly is essential to prevent safety hazards and operational disruptions.

●Inspect pallets for cracks, wear and tear, loose boards, or signs of rot.

●Repair minor damages quickly or remove compromised pallets from the warehousing tasks.

●Keep a preventive maintenance schedule for material handling equipment.

6. Policy and Reporting

Strong policies and structured reporting practices help in ensuring consistency in pallet handling and prevent minor issues from escalating into costly damages.

● Establish clear policies for pallet management, inspection, and reporting damages.

● Encourage staff to log incidents immediately rather than ignoring minor cracks or faults.

7. Use Modern Technology

Leveraging technology such as RFID and IoT is another pallet safety tip and practice that can prevent damage and improve inventory tracking.

●RFID and barcode systems can track pallets in real time, reducing mishandling.

● Use IoT sensors to monitor pallet conditions during transit and in storage.

●Leverage automated storage and retrieval systems (AS/RS) to minimise human error.

- ●Use warehouse management software (WMS) to track pallet locations in real time and optimise pallet handling and placement.

Suggested Read: Best WMS for Small Businesses in the Middle-East

Final Thought

Minimising damage to pallets is essential in warehousing and logistics operations. To achieve this, you need to train staff, invest in high-quality pallets, and utilise modern technologies. Following the right pallet safety tips can help your business minimise pallet damage and ensure your products remain in good condition.

Additionally, you require the right warehouses with a well-designed layout and trained staff. As a trusted warehouse marketplace in the UAE, Cargoz helps you find reliable and efficient storage facilities that reduce handling risks and protect pallets from damage. Contact us to check our warehousing solutions in the UAE.

Frequently Asked Questions

1. What are the most common causes of pallet damage in warehouses?

Pallet damage often results from poor handling, overloading, improper stacking, environmental exposure, and the use of low-quality pallets.

2. How does pallet damage affect warehouse efficiency?

Damaged pallets can slow down operations, cause delays in shipments, increase repacking efforts, and reduce overall productivity.

3. Which type of pallet is best for minimising damage: wood, plastic, or composite?

The best type of pallets for your warehousing and logistics operations depends on their usage, weight load, product type, and environment. Plastic and composite pallets provide longer durability and resistance compared to wooden pallets.

4. What safety risks are associated with broken pallets?

Broken pallets can create sharp edges, loose nails, and unstable stacks that may cause injuries to warehouse staff and damage goods during shipment.

5. How can Cargoz help businesses minimise damage to pallets?

Cargoz helps businesses in the UAE find reliable warehouses equipped with efficient pallet racking systems, ensuring seamless storage and reduced risk of damage.